How to test the fuel injectors?

Introduce

Understanding the proper functioning of fuel injectors is essential to maintaining optimal engine performance. Fuel injectors play a key role in the combustion process by delivering the right amount of fuel to the engine. Regular testing ensures that your fuel injectors are operating efficiently. In this guide, we'll explore some basic fuel injector testing methods to help you diagnose potential problems.

Basic Test Methods

Visual inspection

Begin with a visual inspection to check for any signs of fuel leakage around the injectors. Check the injector o-rings and seals for wear or damage. Check the injector body for corrosion or other physical abnormalities. Ensure that all electrical connections are secure and check the wiring for signs of wear or damage.

Resistance Testing

The resistance test consists of measuring the resistance of the injector coil. Disconnect the electrical connector from the injector and set the multimeter to ohms. Measure the resistance across the injector terminals. Compare the reading to the manufacturer's specifications. If the resistance is significantly high or low, it may indicate a problem with the injector's coil.

Injector Pulse Test

To perform an injector pulse test, connect an indicator or test light to the injector harness. Crank the engine while watching the indicator light. A steady, rhythmic blinking indicates that the proper electrical pulse is reaching the injector. If the indicator light does not flash or flashes irregularly, it indicates a problem with the injector circuit or the engine control module (ECM).

Fuel injector flow test

The flow test evaluates the amount of fuel delivered by each injector. Remove the injectors and connect them to a fuel pressure gauge. Apply power to the injectors while monitoring fuel flow. Measure the flow rate and compare it to the manufacturer's specifications. Differences in flow rates between injectors may indicate a clog or malfunction.

Ultrasonic cleaning

Ultrasonic cleaning is a method of removing deposits from the inside of fuel injectors. First the injector is disassembled and its parts are placed in an ultrasonic cleaning solution. The ultrasonic waves create tiny bubbles that agitate and remove contaminants. After cleaning, the injector is reassembled and flow tested again to ensure improved performance.

Absolutely! Here are three important considerations to take into account when implementing an injector test method:

Safety first

Prioritize safety throughout the testing process. Always disconnect the battery before starting any operations on the injectors. In addition, relieve fuel system pressure to minimize the risk of fuel injection. It is vital that you work in a well-ventilated area and wear appropriate personal protective equipment (such as gloves and safety glasses). Remember that fuel and electrical components can present a hazard, so always exercise caution.

Accuracy of test conditions

To obtain accurate results, it is important to ensure that the test conditions are consistent and precise. Perform the test with the engine off, consulting the vehicle service manual for specific test procedures if necessary. Maintain stable temperature and pressure conditions during the flow test. Any variation in test conditions can lead to inaccurate readings and misdiagnosis of injector problems.

Specialized advice on complex issues

While the methods provided cover basic tests, some injector problems may require specialized knowledge. If you are experiencing a complex problem, such as a persistent engine misfire or a challenging diagnosis, seek the help of a qualified automotive professional or technician. They have access to specialized tools and diagnostic equipment that can identify complex problems and provide accurate solutions. Attempting advanced repairs without the proper knowledge may lead to further complications.

If you want to learn how to check and replace a fuel injector, read this article.

How To Check And Replace A Fuel Injector?

Daysyore's Fuel Injector Buying Recommendations

Daysyore 4Pcs Fuel Injector 6454-53905 For Kubota V2203 V2003 V1903 D1703 Engine

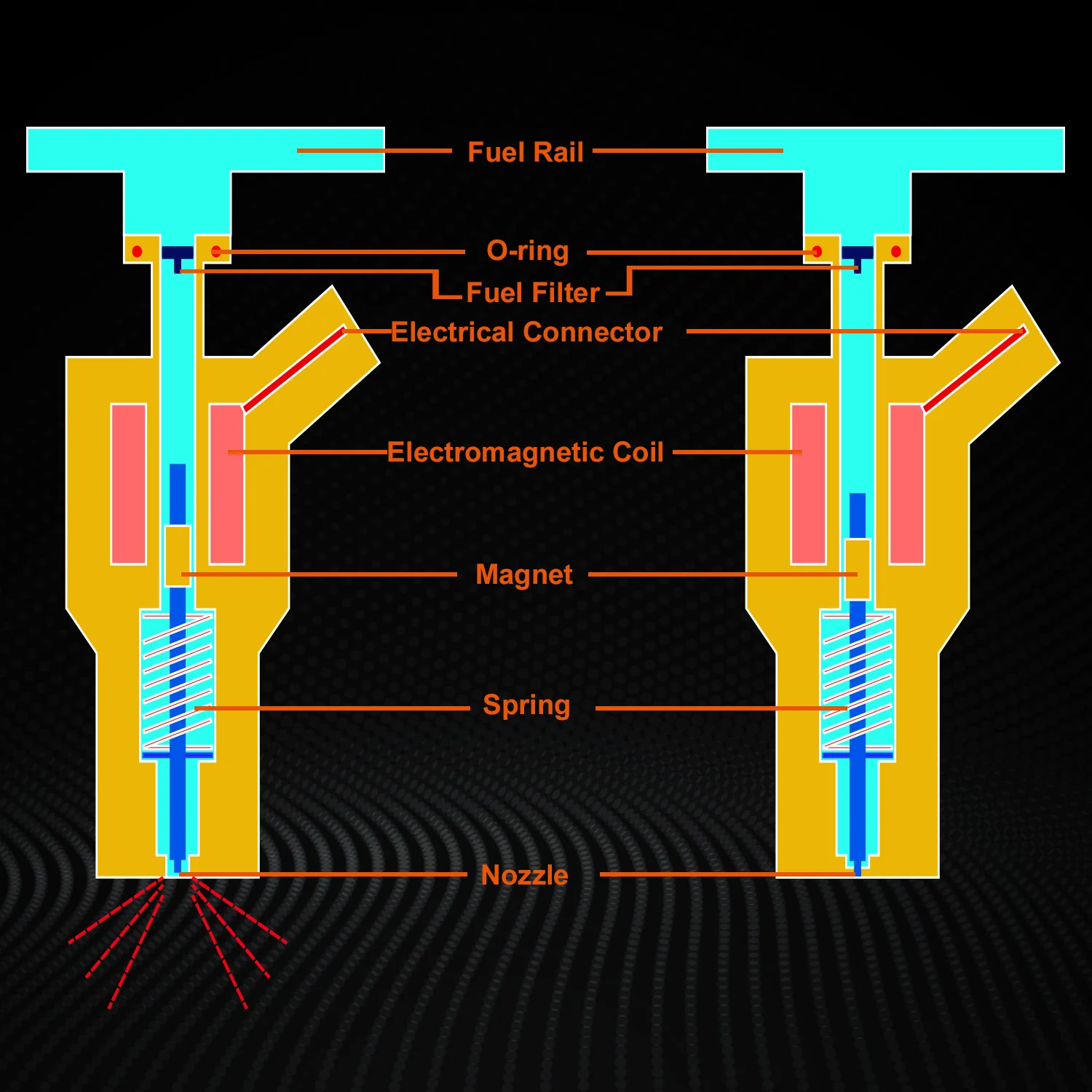

The nozzle is the part of the injector that delivers the fuel into the engine cylinder. It is precisely designed to atomize the fuel into a fine spray to ensure that it mixes thoroughly with the air in the combustion chamber. The nozzle features one small orifice through which the fuel is sprayed. The fine mist or spray pattern also ensures that the fuel burns efficiently and cleanly, with minimal waste or emissions.

Daysyore Fuel Injector 6C5-13761-00-00 For 1999-2020 Yamaha 40-50-60 HP

The solenoid, an electromagnetic valve that controls the flow of fuel to the nozzle, is usually mounted on the side of the injector and consists of a coil of wire, a plunger, and a spring. When the engine control module (ECM) sends a open signal, the solenoid coil is energized, which causes the plunger to move and open the valve. Fuel is then delivered to the nozzle and sprayed into the combustion chamber. When the ECM sends a closed signal to stop fuel delivery, the solenoid coil is de-energized, and the spring returns the plunger to its closed position, stopping the flow of fuel.